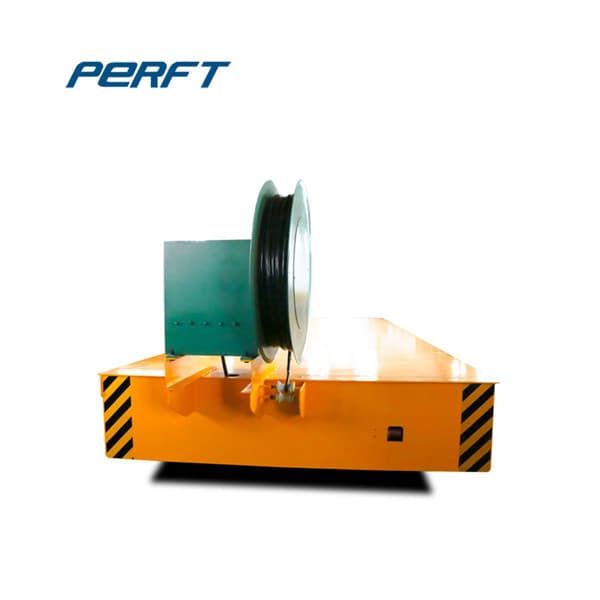

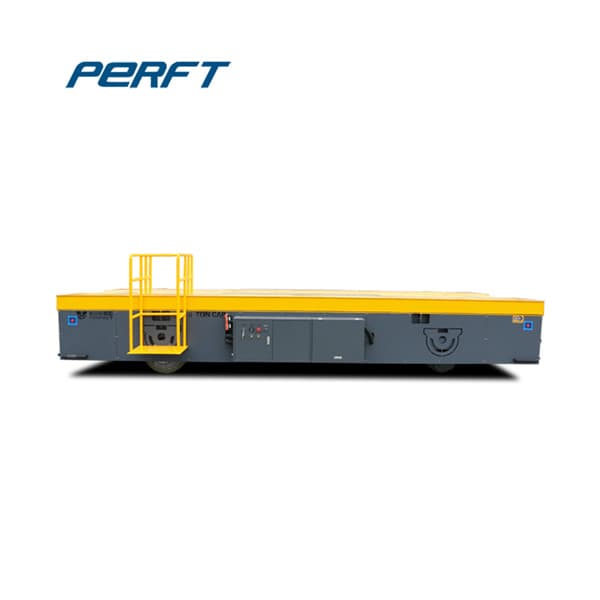

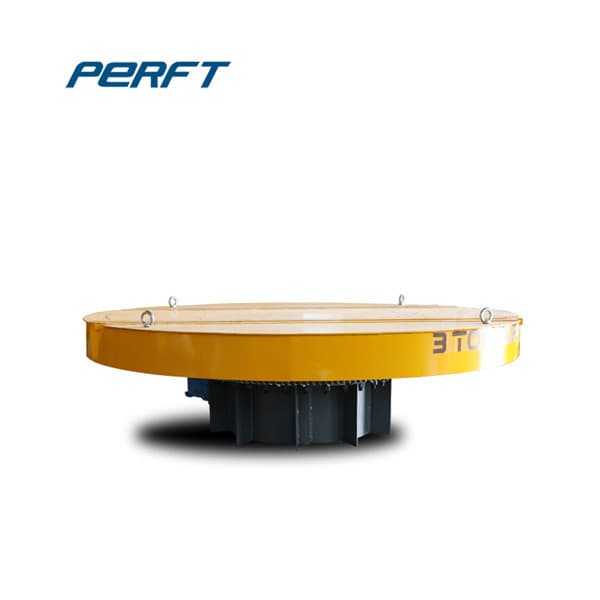

The metal substrate (steel or aluminum) is delivered in coil form from the rolling mills. Coil weights vary from 5-6 tons for aluminum and up to about 25 tons for steel. The coil is positioned at the beginning of the line, then unwound at a constant speed, passing through the various pre-treatment and coating processes before being recoiled.